Industrial floor scales are large, heavy-duty scales for accurately weighing large items or bulk materials in industrial settings. They also determine the weight of a shipment, measure the mass of manufacturing materials, and monitor inventory levels.

Compared to traditional scales that use numeric displays and a few buttons, modern industrial scales feature digital interfaces that can be linked to an electronic device. These allow for easier data collection and analysis.

Given the variety of available scales, finding a product that integrates seamlessly with your current production process is essential. Here are a few factors to consider when selecting the right industrial floor scale for your application:

Areas of Application

You can incorporate industrial scales at nearly every stage of the production process. Consequently, one of the initial steps in the selection procedure must include determining the tasks it will perform. The following are common application areas:

- Order picking for delivery

- Statistical managing for manufacturing processes

- Validating ingredients, production quantities, or product quality

- Weight-based classifying, sorting, and counting

- Weight verifying and integrity testing

Scale’s Capacity and Size

Selecting a scale’s proper capacity and size is essential for obtaining accurate and reliable weight readings. It will also prevent damage to the equipment or the objects being weighed. For example, if an item exceeds the scale’s weight capacity, it may not provide an accurate measurement or even damage the device.

Likewise, the scale’s size and platform determine the dimensions of objects that can be accurately weighed. For example, weighing large pellets requires a scale with a large platform, or it may not accommodate the object’s size.

Quality

Accurate weight measurements are important for quality control, cost management, and compliance with industry regulations. Thus, a precise and properly calibrated floor scale will increase uptime and productivity. Contrarily, inaccuracy can result in issues, including incorrect billing, product waste, and even fines for noncompliance with regulations.

Digital Readouts

Digital readouts are important for industrial scales because they provide simple-to-read and practical measurements. They can also be linked to other systems to facilitate data recording and storage. In addition, they enable customization to specific requirements or applications.

It is strongly recommended that you choose an industrial scale with a digital readout equipped with remote displays and printers. This allows operators to view and record weight data from a distance, which is advantageous for large or complex operations.

NTEP Approval

National Type Evaluation Program (NTEP)-approved industrial scales have undergone testing and evaluation to ensure compliance with National Conference on Weights and Measures standards. This includes assessing the scale’s construction, calibration, and performance under various conditions.

Having NTEP-approved industrial floor scales ensures you are using reliable and accurate devices that can be used for legal trade. This is especially important for businesses dealing with commercial transactions.

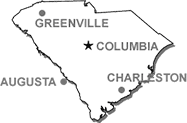

Carolina Scales: Your Trusted Provider of Premium Industrial Weighing Equipment

Choosing the optimal industrial floor scale for your application offers numerous benefits. Some of these are increased productivity, accurate weighing, cost and time savings, and error-free operations.

At Carolina Scales, we combine our industry expertise with exceptional customer service to ensure the best user experience! We provide industrial floor scales with standard models built specifically for various projects and applications.

Visit our website to learn more about our high-quality DIGI and Rice Lake scales! You may also contact us today or request more information about our products and services.