KEY CONSIDERATIONS WITH INDUSTRIAL FLOOR SCALES

Leave a CommentIndustrial floor scales are large, heavy-duty scales for accurately weighing large items or bulk materials in industrial settings. They also determine the weight of a shipment, measure the mass of manufacturing materials, and monitor inventory levels.

Compared to traditional scales that use numeric displays and a few buttons, modern industrial scales feature digital interfaces that can be linked to an electronic device. These allow for easier data collection and analysis.

Given the variety of available scales, finding a product that integrates seamlessly with your current production process is essential. Here are a few factors to consider when selecting the right industrial floor scale for your application:

Areas of Application

You can incorporate industrial scales at nearly every stage of the production process. Consequently, one of the initial steps in the selection procedure must include determining the tasks it will perform. The following are common application areas:

- Order picking for delivery

- Statistical managing for manufacturing processes

- Validating ingredients, production quantities, or product quality

- Weight-based classifying, sorting, and counting

- Weight verifying and integrity testing

Scale’s Capacity and Size

Selecting a scale’s proper capacity and size is essential for obtaining accurate and reliable weight readings. It will also prevent damage to the equipment or the objects being weighed. For example, if an item exceeds the scale’s weight capacity, it may not provide an accurate measurement or even damage the device.

Likewise, the scale’s size and platform determine the dimensions of objects that can be accurately weighed. For example, weighing large pellets requires a scale with a large platform, or it may not accommodate the object’s size.

Quality

Accurate weight measurements are important for quality control, cost management, and compliance with industry regulations. Thus, a precise and properly calibrated floor scale will increase uptime and productivity. Contrarily, inaccuracy can result in issues, including incorrect billing, product waste, and even fines for noncompliance with regulations.

Digital Readouts

Digital readouts are important for industrial scales because they provide simple-to-read and practical measurements. They can also be linked to other systems to facilitate data recording and storage. In addition, they enable customization to specific requirements or applications.

It is strongly recommended that you choose an industrial scale with a digital readout equipped with remote displays and printers. This allows operators to view and record weight data from a distance, which is advantageous for large or complex operations.

NTEP Approval

National Type Evaluation Program (NTEP)-approved industrial scales have undergone testing and evaluation to ensure compliance with National Conference on Weights and Measures standards. This includes assessing the scale’s construction, calibration, and performance under various conditions.

Having NTEP-approved industrial floor scales ensures you are using reliable and accurate devices that can be used for legal trade. This is especially important for businesses dealing with commercial transactions.

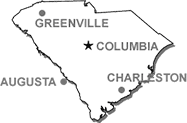

Carolina Scales: Your Trusted Provider of Premium Industrial Weighing Equipment

Choosing the optimal industrial floor scale for your application offers numerous benefits. Some of these are increased productivity, accurate weighing, cost and time savings, and error-free operations.

At Carolina Scales, we combine our industry expertise with exceptional customer service to ensure the best user experience! We provide industrial floor scales with standard models built specifically for various projects and applications.

Visit our website to learn more about our high-quality DIGI and Rice Lake scales! You may also contact us today or request more information about our products and services.

HOW TO PICK THE RIGHT INDUSTRIAL WEIGH SCALES

Leave a CommentChoosing the appropriate weighing scale for your industry can be tedious. However, once you have found the best one for your application, that instrument can bring limitless advantages. Thus, it is important to invest in high-quality industrial weigh scales that can improve the efficiency and profitability of your business.

While most companies look for scales solely on price, assessing the scale’s value and effectiveness in relation to your application is equally crucial. This article will examine the factors to consider when picking the right industrial weigh scales.

Key Considerations When Choosing the Right Industrial Weigh Scales

Research is essential when determining which scale best fits your demands. This will help you choose a device that will not restrict your ability to follow compliance and trade requirements, slow down your operations, or reduce the quality of your products.

Before deciding on a certain product, you should consider the following factors:

Use Of The Scale

Various scales have various features and functionalities, so it is essential to determine how you will utilize the scale. For instance, the scale required for weighing bulk materials and containers would differ from a device for weighing small and light products.

Application Area Or Location

Scales are not one-size-fits-all devices, so not every type will match the attributes and capabilities of your application. Furthermore, the environmental conditions to which the scale will be subjected can range from dirty industrial floors to wet outdoor environments. That said, the location where you will use your scale can significantly impact its performance and expected longevity.

Type Of Materials

You can ponder the following questions to gain a clearer picture of what to purchase:

Would you require a liquid-resistant scale if you were handling liquid?

How likely are the fluids being measured to leak onto the scale?

Is it preferable to use portable scales for weighing lightweight commodities?

For large and bulky products, would you require additional support mechanisms?

Accuracy

The accuracy of many scales is within 0.1% of the actual weight, which is adequate for most applications. However, if you are dealing with a product that is very sensitive to weight changes, you will need a scale that is even more accurate. Also, remember that you can achieve better findings through regular calibration.

Capacity

Each scale is constructed with a different purpose; not all are designed to weigh large materials. Therefore, when purchasing a scale, it is essential to know your maximum and minimum weighing capacities and whether or not the scale requires overload protection.

Readability

A scale’s readability corresponds to the number of decimal places it displays. For example, the readability of a big-capacity industrial weigh scale would be 0.1 lb less than that of a smaller-capacity device.

If you require a high readability level, you should buy a specialized scale, typically one with electromagnetic force restoration. However, these are often costly and sensitive to industrial conditions.

Connectivity

Select a scale that is simple to operate and compatible with other computer systems, devices, and printers. Doing so will allow you to improve quality control, workflow tracking, inventory management, and documentation. You may also opt to buy scales that connect readily to other equipment to automate procedures by controlling their output lines.

Choose Carolina Scales for Your Industrial Weigh Scales Needs

At Carolina Sales, we combine industry-specific product expertise with superior customer service to provide a variety of industrial weighing and measuring equipment. We are professionals in selling and maintaining weighing equipment, including material batching and blending systems, programmable logic controllers (PLCs), and weighing control systems.

You can visit our website to browse through our extensive catalog of products and equipment. You can also contact us, and we will gladly assist you!

EVERYTHING YOU NEED TO KNOW ABOUT RAILROAD SCALES

Leave a CommentOne of the most crucial components of every rail operation is rail weighing. It is an element that aids in expenditure control and compliance in nearly every aspect of train transport — from tracking product shipping and deliveries to avoiding overloading penalties. Therefore, the dependability and accuracy of the methods and technologies utilized throughout the weighing process are critical to obtaining reliable results. And one way to achieve this is through railroad scales.

This article will walk you through everything you need to know about railroad scales, including their importance, procedure, and various types.

What Is a Railroad Scale?

A railroad scale is a weighing technology that uses strain gage systems. It is also used to ensure that the railroad car is not overloaded, which could damage the rail tracks and pose a security risk to the public. In addition, it prevents undocumented cargo and minimizes theft before and after transit.

Several sectors have recently recognized the significance of a railroad scale and have expanded its application for various purposes. For example, the construction and agricultural industries have benefited from rail-scale technology through shipments of industrial parts and food crops recycling.

Importance of Using Railroad Scales

Railroad scales are considered the ultimate technology for accuracy, resulting in cost-effective weighing for transportation and shipping. Here are some of the reasons why these scales are used in a wide range of industries:

To invoice customers for the exact amount of products and goods transported, transaction purposes, and verifying that customers are not overcharged or undercharged.

- To prevent overloading occurrences that could impact infrastructure and avoid eccentric loading that could cause delays and cancellations.

- To ensure that potentially damaging shipment leaks are spotted upon entry at the transfer station to avoid hazardous situations.

- To facilitate chemical components because most existing systems do not possess cavities or structures that lock up air heavier than explosive gasses.

- To align material flow specifications and manage loads during automated bulk loading to gain maximum capacity without overloading.

- To calculate the weight to collect the freight revenue from shippers.

How Railroad Scales Work

The scales are installed on the train tracks. First, the total weight of the cargo within the railroad car is calculated by measuring the vehicle’s mass and then applying the tare weight or the weight of an empty car. Then, you can compare it to other data obtained to ensure that the cargo and everything else is in order.

Most Common Types of Railroad Scale Products

The following are different types of rail scales, with each requiring varying site preparation, scale foundation, and track work to ensure a successful installation:

Pit Design Scale

Railcar scales in pit design are constructed into a trench so that the plate or load cell is at floor level. They operate very similarly to a standard human weighing scale. They also have more complicated mechanisms because railcars must pass over the scale to have their weights measured.

Railboss® Railroad Track Scale

The Railboss® Rail Scale from Rice Lake Weighing Systems is a low-cost and simple-to-install piece of equipment for weighing stationary rail cars. It is operated by Rice Lake’s 920i and Railboss software and comes in eight-section full-draft or four-section double-draft configurations. Furthermore, MS quick-disconnect cable connectors are used on these scales to lessen unprecedented repairs and maintenance.

Here are the scales’ specifications:

Standard Features

- MS quick-disconnect cable connectors

- 80,000 lb. axle capacity

- 320,000 lb. full-scale capacity

- 40,000 lb. rail section capacity

- 115 RE or 132 RE rail sections

- Five ft. 10 in rail sections, pre-drilled for joint bars

Full-Draft Package Features

- (8) 5 ft 10 in rail sections

- 30 ft of connecting cable

- Pre-drilled joint bars with connection hardware

- (2) Rice Lake junction boxes with transient protection

- 30 ft of homerun cable

Double-Draft Package Features

- (4) 5 ft 10 in rail sections

- 30 ft of connecting cable

- Pre-drilled joint bars with connection hardware

- (1) Rice Lake junction boxes with transient protection

- 30 ft of homerun cable

Survivor® PL Low Profile Rail Scales

Another great product by Rice Lake Weighing Systems is the Survivor® PL, a low-profile rail scale design that eliminates the need for a pit to save time and costs on construction and pit maintenance. This rail scale type is deemed to be the highest-performing and the longest-lasting in the industry. The Survivor® PL is manufactured with more steel content than competitive models making it the most durable.

Here are the scale’s other features:

- 100,000 lb capacity compression load cells

- Standard platforms sizes: 12 ft 6 in, 15 ft, 18 ft and 25 ft

- 7 ft 8 in platform width

- 18.5 in profile from top of pier to base of rail

- 24.5 in profile from top of pier to top of rail

- Surge protection kit

- Built-in conduit runs

- 1/4 in bolted checkered steel top plate

- Designed for 115 lb or 132 lb rail (other sizes available)

- Configurations: Single, single/single, single/double, double and double/double

Survivor® RT Rail and Truck Combination Scale

Heavyweight loads need heavy-duty track scales, and this is what Survivor® RT railroad track scale does. This Rice Lake product has a high-quality weighbridge design that creates a rugged, high-precision, heavy-duty weighing system. This pit-type, rail/truck combination scale is perfect for weighing a variety of car sizes, rail cars, and trucks. Survivor® RT is also ideal for bulk cement, aggregate, grain, scrap metal, and chemical applications.

Here are the scale’s specifications:

- 200,00 lb capacity compression load cells

- Standard platform sizes: 60 ft, 66 ft, 70 ft, 72 ft, 80 ft, 90 ft, and 100 ft

- 4 ft 9 in profile

- Factory welded modules

- Steel or concrete deck

- Lightning and surge suppression kit

- In-bridge conduit runs

- 7 in reinforced concrete deck design

- (1) 24 in square manhole ring and cover

- Fully assembled factory-welded modules

Carolina Scales for High-Quality Industrial Weighing Equipment

At Carolina Sales, we integrate our industry product knowledge with exceptional customer service to meet and exceed our customers’ expectations. We are experts in the sale and service of weighing equipment, such as material batching and blending systems, PLCs, and weighing control systems. We also offer full calibration services and one of the most extensive rental scale selections available.

Contact us today to learn more about our services and capabilities or request information to start your next project with us!